When hydraulic cylinders fail or show signs of wear, many businesses consider replacement as the only option. But what if there was a cost-effective, sustainable, and efficient alternative? That’s where cylinder rebuilding steps in. By restoring damaged or worn cylinders to like-new condition, rebuilding extends the life of your equipment and saves your bottom line.

In this blog, we’ll walk you through how the cylinder rebuilding process works, its benefits, and why it’s a smart choice for heavy-duty industries.

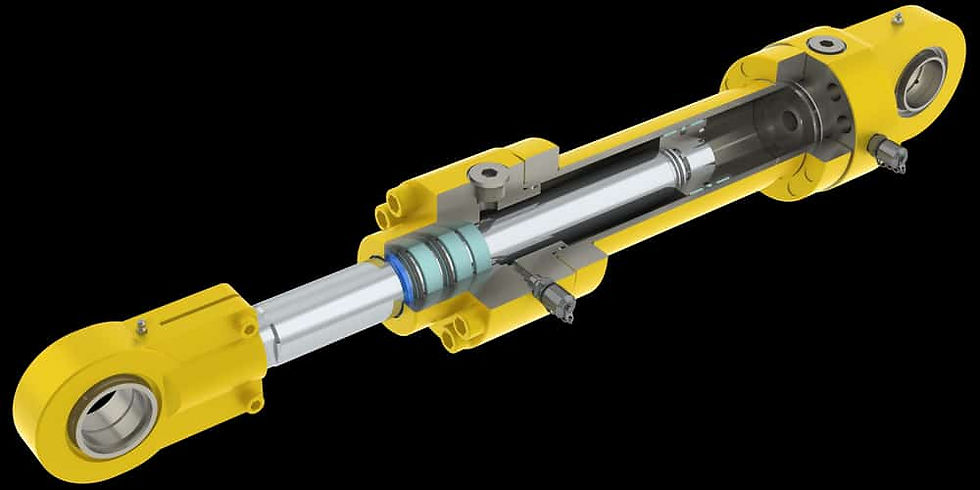

What Is Cylinder Rebuilding?

Cylinder rebuilding is the process of disassembling, inspecting, repairing, and restoring hydraulic or pneumatic cylinders to optimal working condition. Instead of replacing a damaged cylinder, rebuilding allows you to reuse its core components while addressing issues like:

Worn or damaged seals

Bent or corroded rods

Leaks or low-pressure performance

Cracked cylinder barrels

The result? A rebuilt cylinder that performs as well as a new one but at a fraction of the cost.

The Cylinder Rebuilding Process

Here’s a step-by-step look at how professional cylinder rebuilding works:

Disassembly and Inspection

The cylinder is carefully dismantled, and each component is inspected for wear, damage, or failure. Technicians use advanced diagnostics to identify underlying issues.

Cleaning and Preparation

All components are cleaned to remove debris, dirt, or contaminants. Damaged parts, such as seals or rods, are identified for replacement or repair.

Machining and Repairs

Components like rods, pistons, or barrels may be machined, straightened, or honed to restore their original dimensions and function. Cracked parts are welded or replaced.

Seal Replacement

Worn seals are replaced with new, high-quality seals to ensure leak-proof performance and maintain system pressure.

Reassembly and Testing

The cylinder is reassembled with precision, and rigorous testing is conducted to confirm it meets pressure, alignment, and performance standards.

Why Choose Cylinder Rebuilding?

Cylinder rebuilding offers several key benefits that make it an attractive option:

Cost-Effective: Rebuilding is often 50-70% cheaper than buying a new cylinder, helping you save on equipment costs.

Sustainability: Reusing cylinder components reduces waste, making rebuilding an environmentally friendly choice.

Faster Turnaround: Rebuilding services can often be completed faster than sourcing a new replacement.

Extended Equipment Life: By restoring cylinders to optimal condition, you extend the lifespan of your machinery.

Custom Solutions: Rebuilding allows for modifications or upgrades to meet the specific demands of your equipment.

Common Applications of Cylinder Rebuilding

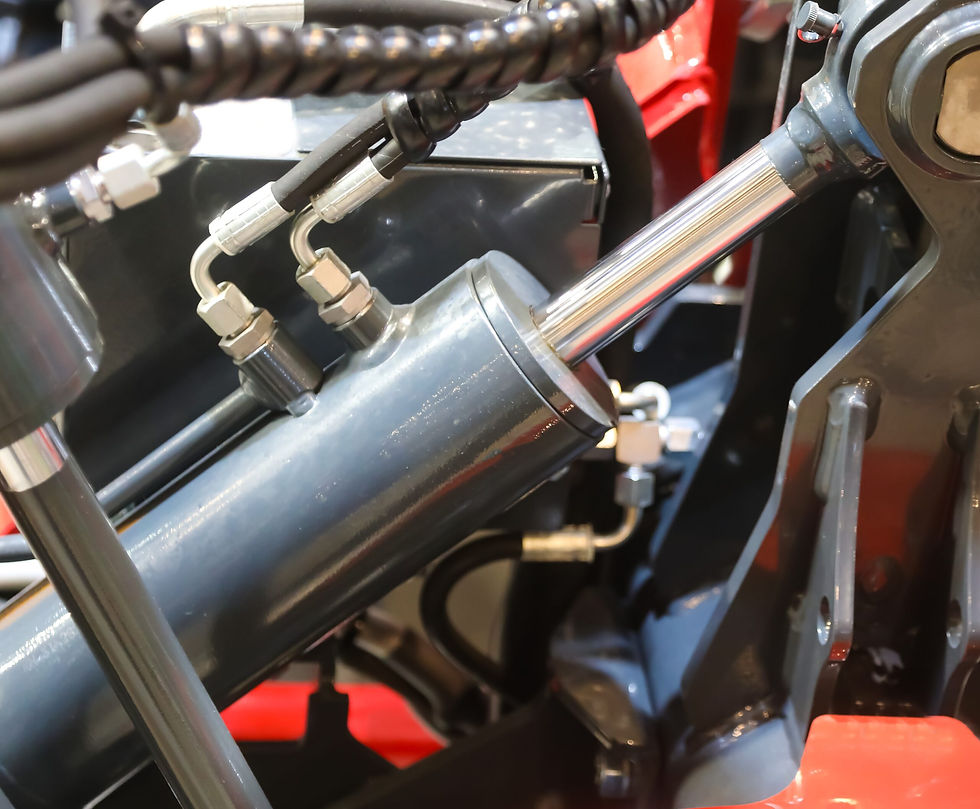

Industries that rely on hydraulic and pneumatic systems can benefit significantly from cylinder rebuilding, including:

Construction: Excavators, loaders, and cranes often face wear from heavy use, making rebuilding essential.

Mining: High-pressure cylinders in mining equipment need regular maintenance to stay operational.

Manufacturing: Assembly lines and presses rely on precise cylinder performance for efficiency.

Signs Your Cylinder Needs Rebuilding

If you notice any of these issues, it may be time to consider cylinder rebuilding:

Visible leaks or reduced pressure performance

Sluggish or erratic equipment movements

Bent or corroded rods

Excessive heat generation during operation

Addressing these issues early can prevent costly downtime and ensure your equipment operates at peak efficiency.

PSI Hydraulics: Your Cylinder Rebuilding Experts

At PSI Hydraulics, we specialize in delivering high-quality cylinder rebuilding services tailored to your needs. With decades of experience, advanced facilities, and a commitment to precision, we help extend the life of your equipment and keep your operations running smoothly.

Ready to Rebuild? Contact PSI Hydraulics Today!

Don’t let a worn cylinder slow you down. Rebuilding is a cost-effective, sustainable solution that keeps your equipment in top shape. Contact PSI Hydraulics today to learn more about our cylinder rebuilding services or schedule a consultation with our experts.

.png)

Commentaires